Blog

What is CNC Machining and How Does it Work?

Cadrex constantly welcomes new technologies to create and deliver quality products for our partners. We often leverage CNC machines for efficient, precise, and repeatable results.

February 15, 2023

Cadrex’s services and capability offerings constantly change as we discover and incorporate new technologies. Innovative companies in a myriad of industries rely on Cadrex to produce, assemble, and deliver high-quality products. We constantly welcome new technologies and can combine capabilities to create products that meet our partners’ needs. Machining is one of the many critical capabilities we offer, and we often leverage computer numerical control (CNC) machines for repeatable results.

Start with a Good Design

Before setting our CNC machines into motion, we start with a good design. At Cadrex, we utilize state-of-the-art engineering software, 3D printers for concept development, and various prototyping tools to offer design for manufacturing (DFM) and design for assembly (DFA) services. Cadrex is a CNC company that can also assist in design for manufacturability. Our experienced operators carefully and thoughtfully evaluate the part or parts our clients wish for us to manufacture, offering insight and suggestions as to refinements that could simplify the production process.

What is a CNC Machine?

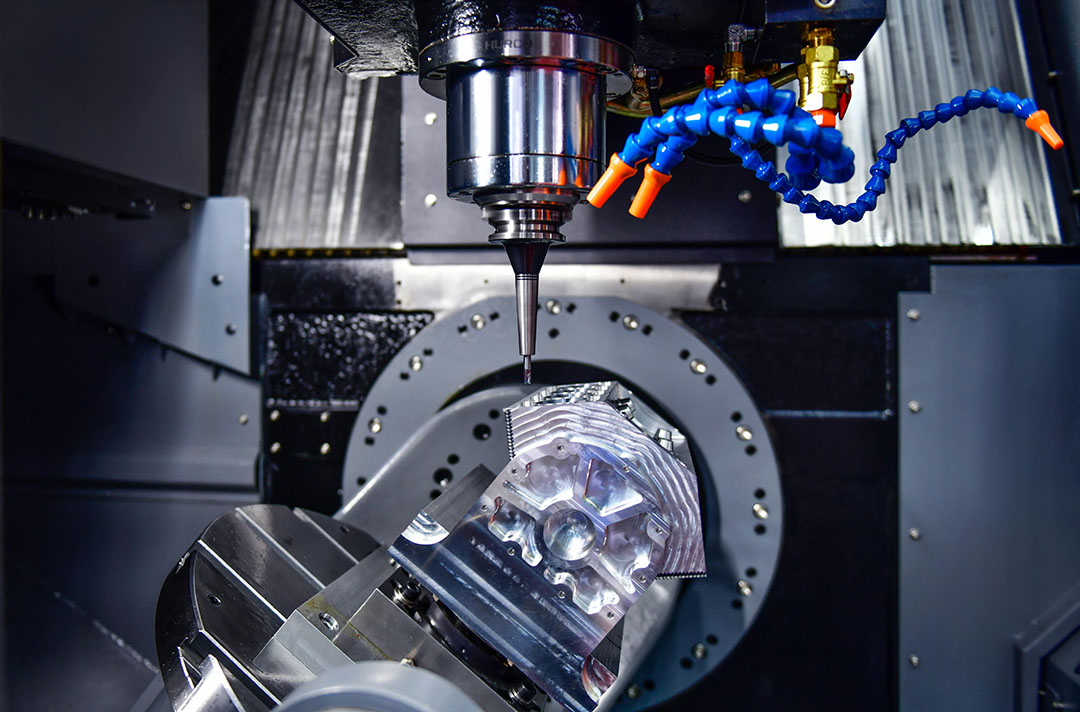

Precision CNC machining is the use of CNC machines to turn a raw piece of material into a desired (and precise) shape. A CNC machine is an automated machine that performs tasks programmed by digital software. With CNC machining, knowledgeable workers can operate a fleet of machines by utilizing computer software.

Types of Precision CNC Machining

Our array of available machinery allows us to accommodate multiple setups, even with little notice. We have CNC machine centers that provide vertical, horizontal, and 5-axis CNC machining services as well as an extensive tool room that is fully equipped with milling, lathe machines, and more.

Our precision CNC machines can be split into two main categories: CNC machining centers and CNC turning centers.

CNC Machining Centers

Many CNC machining centers can provide some mix of milling, drilling, boring, tapping, and reaming in a single system. These centers come with an automatic tool changer and a table that clamps down what’s being machined to minimize its movement. On this type of CNC machine, the tools move but the machined product does not. CNC milling is utilized in our facilities for prototyping and modeling of materials like metal or plastic.

When it comes to the difference between these types of CNC machining centers, it all has to do with the direction of the machine’s spindle and the tool attached. For example, a horizontal milling machine has a spindle that is mounted horizontally. Vertical machining centers can be used for drilling and plunging cuts, while horizontal machining centers are usually used to create grooves on a machined piece.

CNC Turning Centers

Think of CNC turning centers like an automated lathe — while CNC machining centers use moving tools to machine a part that does not move, a CNC turning center works in essentially the opposite way by rotating the part instead, keeping the tools fixed.

CNC turning centers are usually used to create cylindrical parts due to the way the machine operates. We often use CNC turning to build prototypes, spacers, shafts, or bushings below 2.5 inches.

Benefits of Working with a Precision CNC Machining Company

There are numerous benefits to working with a manufacturing company that has state-of-the-art CNC machines. Expect a high production rate, with minimal to no error, and uniform results. Without worrying about the results, you can instead focus on getting assistance bringing an idea into fruition.

Integration and Electromechanical Assembly

In addition to machining, Cadrex offers multiple levels of mechanical assembly and finishing. We can truly build your product from start to finish — from design assist to assembly. This includes electromechanical assembly, which involves putting together parts that control the flow of electricity through mechanical equipment. Precision CNC machinery is often used to create the parts used for such equipment with repeated results.

As new technologies emerge, more and more, they have some power component to them. We make it a priority to follow and anticipate trends to ensure we can offer the electromechanical assembly support our customers require.

Our workforce performs a wide variety of functions, including:

- Torch Brazing

- Nitrogen Leak Detection

- Hydrostatic Leak Detection

- Helium Leak Detection

- Hi-Pot/Ground Continuity Testing

In addition to performing bench or cell work, we help our customers obtain certification and can even drop ship finished parts to simplify the supply chain.

Flexible Manufacturing System

No matter what project we undertake, our goal is always to manufacture or assemble a product that meets or exceeds quality and tolerance requirements. To consistently meet this goal in an efficient and timely manner, we leverage a flexible manufacturing system (FMS). This is a method of production that can swiftly conform to adjustments in the manufacturing process, such as product specifications or quantity. In general, an FMS helps to improve manufacturing efficiency and reduce production costs.

Designed for processing low-volume, high-mix components, the FMS we use with many of our CNC machines includes dedicated pallet systems for a family of components. If you are a customer who regularly needs a specific part or part that is from a larger product family, or if you need support for overflow production, our FMS capabilities will benefit you.

Expect Superior Service

All of the types of precision CNC machining that we use, whether they are machining or turning centers, help us to achieve the high quality of products that our customers have come to expect. We approach every project we undertake with the same end goal: to manufacture or assemble a product that exceeds our partners’ expectations. The expert engineers, programmers, and operators at Cadrex utilize our state-of-the-art equipment to build precision parts and assemblies for innovative customers.

Recent Insights

News

Blog

White Papers