System Integration & Testing

home / capabilities / system integration & testing

End-End Solutions

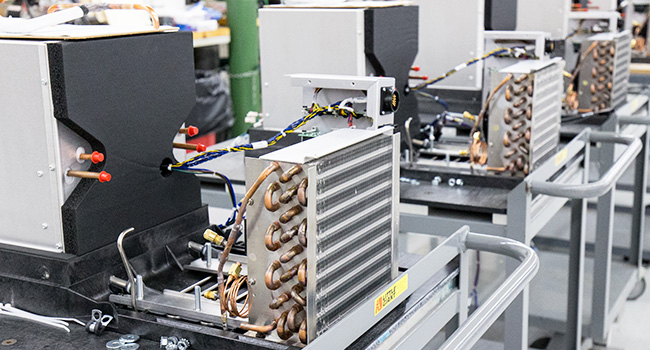

Our services go beyond manufacturing to include mechanical assembly, integration, and testing. Keeping your assemblies and programs with a single vendor eliminates the risks associated with moving custom components.

We work closely with our customers to understand the entire scope of the project, whether it’s a simple assembly or complex integration with custom and purchased components that requires testing to ensure all of the pieces come together smoothly.

Integration & Testing Capabilities

-

Custom Metal & Plastic Components Integration

-

Integration of Purchased Components

-

Racking, Stacking, Validation, and Testing

-

Integrate Fully Functional Tested Plug-in Units, RF-modules, Processing Units, Power Supplies, and Power Distribution

-

ESD Protection for Critical Electronic Components

-

Thermal Production and TUV/UL/CSA Certification Standards

-

Nitrogen, Hydrostatic, and Helium Leak Detection

-

Hi-Pot/Ground Continuity Testing

Case Study

Cloud Networking Company Cuts Time to Market by 50%

Cadrex helped Company X get their products through production and testing and into the market faster while eliminating ocean transit times and mitigating geopolitical risks.

Experience Matters

Cadrex has worked with technology industry leaders for decades, delivering innovative solutions for electromechanical assemblies and testing requirements. Our technicians can integrate various components, including midplanes, bus bars, power supplies, server storage, cabling, and more. If required, integration and testing can be performed in a climate-controlled area to ensure a dust-free and clean environment.

Related Links

Blog

What To Look For When Sourcing Large Sheet Metal Enclosures

Sheet metal enclosures come in all shapes and sizes. It’s the larger ones, however, that often cause designers and manufacturers the most grief...

Blog

Transitioning Outdoor Electrical Enclosures And Fiber Optic Boxes To Plastic

Designing outdoor electrical enclosures or fiber optic boxes? There might be some excellent reasons to switch from metal to plastic, but it’s a good idea to first talk to a manufacturer that does both....

Blog

Should Your Sheet Metal Manufacturing Partner Be Tech-Savvy?

There’s no shortage of reasons for manufacturers to embrace automated sheet metal production and other forms of advanced manufacturing technology...