Blog

Quality and Precision: Why Quality Assurance is Important in Precision Machining

At Cadrex, we make dreams become reality. We take a design and turn it into something real; we make a thought tangible. Our precision CNC machines and other core capabilities yield high-quality products for our partners across industries, and nothing can be too precise.

February 15, 2023

What is Precision Machining

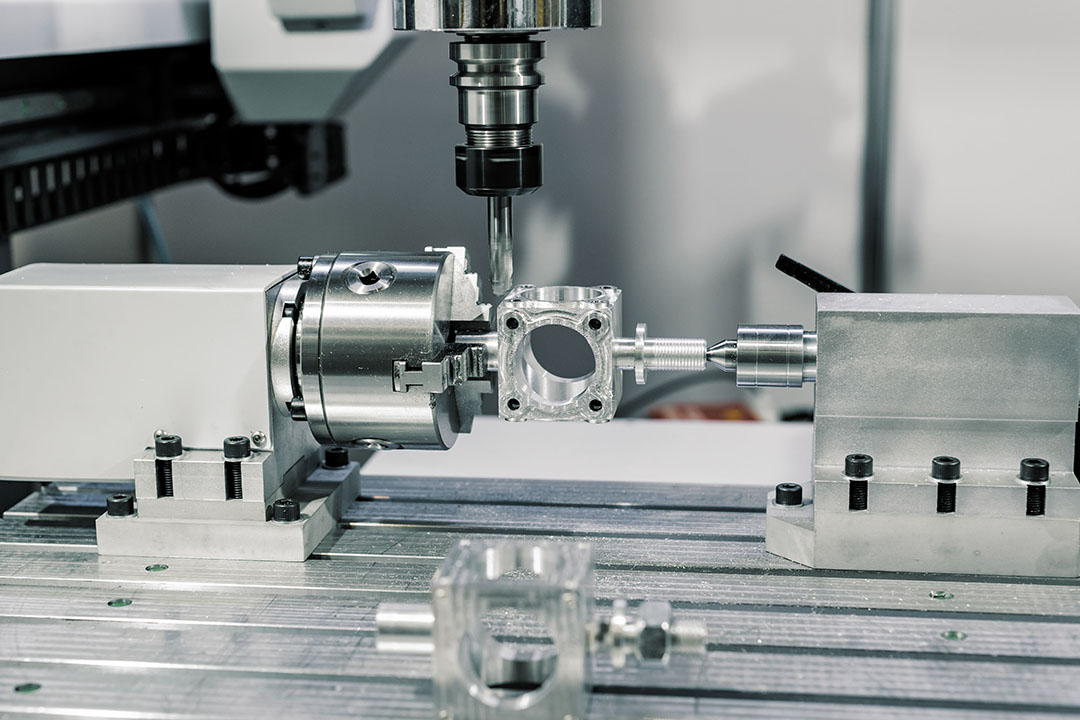

The definition of precision machining is right in the name — a precision machinist takes a piece of raw material and shaves it down to the desired and specified shape while measuring and cutting to the exact specifications. The degree of exactness, or tolerance, needed depends on the product. The smaller the tolerance, the more precision is needed. Often, this comes at a higher manufacturing cost. By analyzing the product from design to completion, we can offer high-tolerance, high-quality manufacturing… saving money for our clients while maintaining excellency.

At Cadrex, we leverage a vast array of precision CNC machines and utilize our other core capabilities to handle client projects of all sizes. We can tap into resources at any of our facilities across North America to create the perfect product. Our facilities in North America include a plethora of precision machining equipment, such as:

- More than 200 CNC machine centers with vertical, horizontal, and 5-axis.

- Flexible manufacturing systems, including business intelligence, robotics, and automation.

- An extensive tool room with milling, lathe machines, and more.

- Robotic cells: industrial robots to increase productivity and lower labor costs.

To learn more about CNC (Computer Numerical Control) Machining, read our blog post “What is CNC Machining and How Does it Work?”

Robotic Cells in Precision Manufacturing

When it comes to precision manufacturing, accuracy and speed are critical to the success of an operation — and robotic machining cells ensure these benefits. A robotic cell is a complete system that includes a robot, a controller, an enclosed space for the robot to operate, and additional components that allow the robot to complete multiple tasks.

Benefits of Robotic Cells

While there are generally regulations in place to limit the speed of a robot within the presence of a human worker, the robotic cell provides various barriers to remove this limitation. This allows the robots to perform complex machining tasks with impeccable accuracy and speed. Cell operators can load and unload parts while the robot works on alternative tasks. This efficiency is combined with flawless consistency, resulting in a repeatable process with repeatable results.

Additionally, automated systems work faster and longer for a lower cost — and this is further compounded with the presence of a cell. Instead of wages and benefits, these systems require maintenance. But as technology improves, the cost of maintaining and repairing robotic systems goes down, resulting in savings for operating companies and customers.

While efficiency and savings are critical, it is of the utmost importance to keep workers safe while operating machinery. Robotic cells can handle tasks that could pose a safety risk to humans, such as working with sharp tools, heavy machinery, or caustic chemicals. The safety barriers of the cell allow the robot to quickly accomplish these tasks without posing any risks to operators.

Quality Assurance in Manufacturing

Quality assurance is necessary to get the desired results when working with precision CNC machines. Companies that operate precision CNC machines should meet the ISO quality management standard, which is based on the following seven principles:

- Customer focus

- Leadership

- Engagement of people

- Process approach

- Improvement

- Evidence-based decision making

- Relationship management

At Cadrex, we are proud to say that both our precision manufacturing capabilities and quality assurance procedures are second to none, as exemplified by our ISO-9001 certification. We build a custom quality plan for each product. You can learn about our quality assurance program and see our eight industry certifications on our Quality Standards page.

Business Intelligence and Production Monitoring

It’s not enough to be the best — you can always strive to be better. Our facilities embody the concept of continuous improvement, which we accomplish by retrieving, sorting, and displaying up-to-the-second information on our most critical jobs. We pursue continuous improvements on our production floors by utilizing business intelligence and production monitoring systems.

Our state-of-the-art, highly efficient robotics and automation machines benefit from business intelligence programs, which analyze data, maintain quality control, and keep production running smoothly. These production monitoring systems allow operators to oversee production on several automated machines across an entire factory.

Read more about our analytics and business intelligence capabilities on our BI, Automation & Robotics page.

Why Partner with Cadrex for Precision Machining Projects?

No matter the scale of your project, Cadrex can handle it.

We undertake our precision machining services with superior efficiency in mind, carrying out our manufacturing to achieve decreased lead times for customers. Our teams leverage state-of-the-art precision machining equipment and industrial robots in the cells on our shop floor. These robots not only allow skilled employees to focus on other work, but they also increase productivity and lower labor costs for our customers.

At Cadrex, we can combine our precision manufacturing efforts with our breadth of core capabilities to seamlessly move one product from design to assembly. Our teams are ready to step in and work alongside you to manufacture an exceptional product.

Recent Insights

News

Blog

White Papers